Although quality is a complex and multifaceted concept, high-quality parametric CAD models in an engineering design context can be briefly defined as 3D models that are free from geometric and topological errors, can be modified without causing regeneration errors that may hinder reusability, and properly convey design intent. The financial cost of low-quality models is significant. Multiple non-formal evidences show that although most companies do acknowledge the problem [BRC14], they are unable to determine its scope or accurately measure the impact on other business processes. In many cases, companies assume that there are inherent inefficiencies in processes that involve virtual models, and grudgingly accept the associated costs. Furthermore, firms are generally reluctant to openly discuss the prevalence of low-quality models in their organizations, as it would require admitting inefficient business practices. Interestingly, the problem of parametric CAD quality has received little attention from the research community.

The reason for this poor quality of models is the result of several situations. Education and training, both at the university and at companies that provide technical training or CAD software providers, usually focus on learning the functionality of the software package. However, knowing the functionality is not enough to generate good CAD models. A strategic knowledge of the CAD tool is key to getting models that can be edited and reused in the future [*CCO15]. Some large companies address these problems by developing modeling guidelines or standards that guide designers and engineers in their modeling tasks. These types of documents are not publicly available, and therefore, their effectiveness and efficiency have not been demonstrated. In the public domain, there are very few examples of formal modeling methodologies. The few that exist are focused on solid modeling, such as patent-protected horizontal modeling [LK04], resilient modeling [Ger22] (accessible through a fee-based website) or modeling based on explicit references [BRC14] described in a paper.

The parametric modeling process

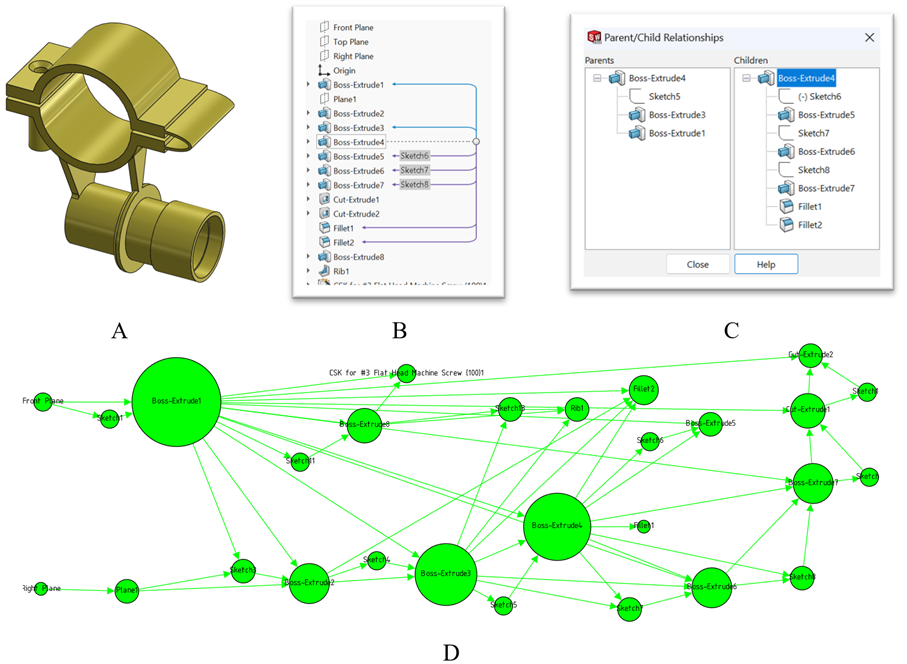

In a typical parametric feature-based modeling process, geometry is built by gradually combining a series of features in a specific sequence (commonly managed through a model tree). These features are controlled by parameters (as they are built by sweeping parameterized profiles) and organized in parent-child relationships (because they are linked to each other by references both directly or through datums, when a parent feature is changed, its child features are updated accordingly [BLV20], [SM95]). From a designer’s standpoint, many decisions must be made during the modeling process, as a virtually unlimited number of strategies can be used to build the geometry. The robustness and flexibility of the model largely depend on how features and datums are connected and organized internally. As a parametric model becomes more complex, its parent-child dependencies and their degree of interconnectedness also increase, which makes the model harder to maintain and the subsequent geometry modifications difficult to predict and execute [*AJA21], [*AJC22]. An example illustrating these concepts is presented in the next Figure.

The notion that parametric modeling enables users to build some sort of “intelligence” into their models refers to the ability of the geometry to inherently represent design intent within its structure so that it can adapt to changes easily and effectively [*OCC18].Poor modeling practices and dependency management typically result in models that are difficult to alter and require considerable amounts of rework [LPG18], [OST20] (for example, strategy B in Figure 3). Some formal modeling methodologies have been proposed to mitigate the aforementioned problems, most notably horizontal modeling [LK04], explicit references modeling [BRC14], and resilient modeling [Geb22]. Although we have tested and confirmed that some of these methodologies provide a positive impact [*CCC16], there is significant room to improvement. In our view, the methods developed so far (like [Her21], or [Geb22]), are remarkable contributions, but still incomplete approaches. Hence, a method that contemplates the different aspects of the quality of the CAD models is necessary.

Levels of quality

In our previous research, we stated that CAD quality is a complex and multidimensional construct. Indeed, we defined the six main dimensions of CAD quality as validity, completeness, consistency, conciseness, clarity, and the ability to convey design intent [*CCO15]. In this project, we advocate for clustering these dimensions into three main levels to measure whether CAD models are (1) usable, (2) reusable, and (3) semantically rich. Models that are usable should be ranked as “acceptable,” models that are also reusable as “good,” and models that, in addition to being usable are reusable, are semantically rich as “excellent.” These three levels will form the skeleton of our formal methodology.

In our view, usability encompasses validity and completeness, reusability characteristics include consistency and conciseness, and a semantic-rich model implies clarity and the ability to convey design intent [*CCJ14]. Current quality checkers for CAD models barely assess the validity of models. Available commercial Model Quality Testing (MQT) systems only provide automatic mechanisms to identify the geometrical and topological errors described by standards such as VDA 4955 and SASIG PQD 2.1. However, aspects related to the verification and effective implementation of design intent, as well as measuring the capability of 3D models to be reused, adapted, and modified, are not supported [*GCC17].

Many academic studies encourage consistency in CAD models [*GPP21]. However, a recent study demonstrated that sketch consistency in procedural CAD models (an aspect of the broader consistency dimension which results from the best practice in CAD that encourages fully-constrained sketches) is very unusual. Only a 2.5% of the sketches analyzed on 2 million models created with PTC Onshape during the period from 2015 to 2020 were completely constrained [SOZ20] There are also studies on conciseness and clarity aimed at ensuring reusability in CAD models [*AJA21] [NEN21] [Her21] [Geb22]. However, these dimensions of CAD quality have received comparatively less attention from industry. Except for the work carried out previously by our group, there are no previous references to analyze the impact of modeling methodologies from the point of view of quality.

Finally, there is a recent research activity around considering how CAD models convey design intent [RM21] [RMC18] [RMZ17] [KA21] [MOR16] [*OCC18] [*CNC20]. Some authors put the focus on the differences between declarative, procedural, and strategic knowledge [DTS12] [DSD20] [GGM19], which resonate with the levels that measure whether CAD models are usable, reusable, and semantically rich.

Adecuacy of characteristics and the purpose of selected modality

Our proposal aims to generate synergies between three different institutions, Universitat Politècnica de València (UPV), Universitat Jaume I (UJI) and Mondragon Unibertsitatea (MU) that share a vision focused on quality around CAD technology. The history of collaboration in this field between UPV and UJI goes back more than 20 years, with the publication of the most cited paper worldwide on the topic of product data quality [*CPV02]. Since then, constant activity has been maintained in this field, which has been joined since 2021 by the collaboration with Mondragon Unibertsitatea that has already borne its first fruits [*AJA21], [*AJC22]. The CAD-Q project will serve to reinforce this scientific cooperation scheme that has been successful to date and enhance the internationalization of the group through its relationship with Purdue University that began in 2019.

The proposal combines the generation of new scientific knowledge and its application to solve an important problem in all those industrial sectors that use parametric CAD tools for the geometric definition of their products. The collaboration with the companies that have expressed their interest in the results of the project, will allow, during its execution, a first transfer of results. The ambitious dissemination plan to be carried out will make the results of the project available to the industrial sectors mentioned above.

Justification and expected contribution of the project to solving specific problems linked to the selected thematic priority

The proposed CAD-Q project is aligned with the thematic priority “Digital world, industry, space and defense” from the State Plan for Scientific, Technical and Innovation Research 2021-2023 that is deployed in four main axes: (1) digital transformation and artificial intelligence, (2) industrial transition, (3) R&D and innovation in space, and (4) R&D and innovation in the defense sector.

In the context of Industry 4.0, the digitization of industrial value chains will increase efficiency and flexibility in production processes and reduce costs while increasing quality. In this context, the CAD-Q project is of particular relevance because leading manufacturing companies organize their activities based on the digital representation of the product. In these scenarios, CAD models become the source of truth and the primary elements that support the design, analysis, and manufacturing activities.

Since 3D CAD models are the fundamental elements that support the design process of most products, from the most complex and innovative—such as those developed by the automotive and railway industries, with a strong presence in Spain—to the more traditional ones, such as home appliances, furniture, and toys, there is no doubt that the results of the proposed project can have a positive impact on the economy. The impact will presumably be greater in small and medium-sized companies, which, because of their size, cannot generally allocate resources for the development of internal methodologies for working with CAD tools as larger organizations can.